YAS PWM STEEL

YAS PWM HLAU DAIM HLAU

YAS PWM HLAU TUAG TUA

Cov Khoom Kub Ua Haujlwm Hlau

Yas Tuaj Hlau

YAS PWM HLAU TUAG TUA

Khoom :

- Hnav tsis kam

- Polishability

- Machinability

- Tawv thiab tawv tawv

- Thermal conductivity

Daim ntawv thov:

MOLD STEELS feem ntau muaj cov pa roj carbon tsawg dua - 0.36 txog 0.40% thiab chromium thiab npib tsib xee yog cov ntsiab lus alloying. Cov yam ntxwv no pub rau cov ntaub ntawv no rau polished ua tiav qhov kawg siab.

Mas yas Yas Pwm Hlau Qib No. Peb tau muab:

| KEEB KWM |

DIN |

ASTM |

JIS |

| HSM83 | 1.2083 | 420 | SUS420 |

| HSM 16 | 1.2316 | ||

| HSM11 | 1.2311 | P20 | |

| HSM38 | 1.2738 | P20 + Ni |

TSHUAJ TUA KWV TIJ

|

KEEB KWM |

DIN |

ASTM |

TSHUAJ TUA KWV TIJ |

NEEG LAUS |

DAIM NTAWV THOV |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

N |

|||||

|

HSM83 |

1.2083 |

|

0.36-0.42 |

1.0 |

1.0 |

0.030 |

0.030 |

12.50-14-50 |

|

0.20 |

(0.60) |

zoo tshaj plaws polishability, zoo corrosion kuj, thiab zoo coj kuj. cov khoom siv ntawm kev xaiv rau kev tsim cov yas molding cov cuab yeej uas xav tau cov siab tshaj plaws zoo-polished fi nishes |

moulds rau kev ua kom tsis sib haum (CDs), cov cuab yeej siv kuaj mob, tsom iav kho qhov muag, thiab lwm yam, uas yuav tsum muaj qhov tsis zoo. |

|

HSM16 |

1.2316 |

|

0.33-0.45 |

1.0 |

≤ 1.50 |

0.030 |

0.030 |

15.5-17,5 |

0.80-1.30 |

- |

≤ 1.00 |

siab huv / homogeneity, muaj zog tiv taus xeb thiab xeb, zoo polishability, feem ntau muab tso rau hauv quenched thiab tempered mob nrog lub zog ua haujlwm ntawm kwv yees li 300 HB. |

Rau Pwm nrog lub cev muaj zog tsis kam tiv thaiv siv rau lub koob yees duab lens, Dies rau nias cov tshuaj lom neeg sib tov |

|

HSM11 |

1.2311 |

P20 |

0.35-0.45 |

0.20-0.40 |

1.30-1.60 |

0.030 |

0.030 |

1.80-2.10 |

0.15-0.25 |

- |

- |

Prehardened yas ua pwm hlau, tawv tawv nyob rau hauv raws li muab cov kev mob 280-320 HB uas yog tus cwj pwm zoo los ntawm kev ua kom zoo ntawm qhov nruab nrab lub zog zoo polishability thiab etching muaj peev xwm, txaus xeb ua tau zoo, thiab tus nqi ef mach cient machining cov yam ntxwv. |

Yas pwm, Pwm ntas rau yas pwm thiab siab casting tuag, Raus siab rau cov kis thiab cov cuab yeej thiab cov cuab tam tuag rau zinc. |

|

HSM38 |

1.2738 |

P20 + Ni |

0.35-0.45 |

0.20-0.40 |

1.30-1.60 |

0.030 |

0.030 |

1.80-2.10 |

0.15-0.35 |

- |

0.90-1.20 |

Prehardened yas mould steel, hardness nyob rau hauv raws li muab cov xwm txheej 280-320 HB Cov ntsiab lus siab nickel (1%) tau tshwj xeeb kom paub meej qhov zoo tshaj plaws homogeneity ntawm cov qauv thiab hardness los ntawm thickness txawm rau cov tuab heev, zoo polishability, txaus corrosion tsis kam, zoo machinability. |

Loj loj Yas Txhaj thiab tshuab moulding tuag, pwm ncej rau siab casting tuag, Raus siab rau cov neeg tau txais |

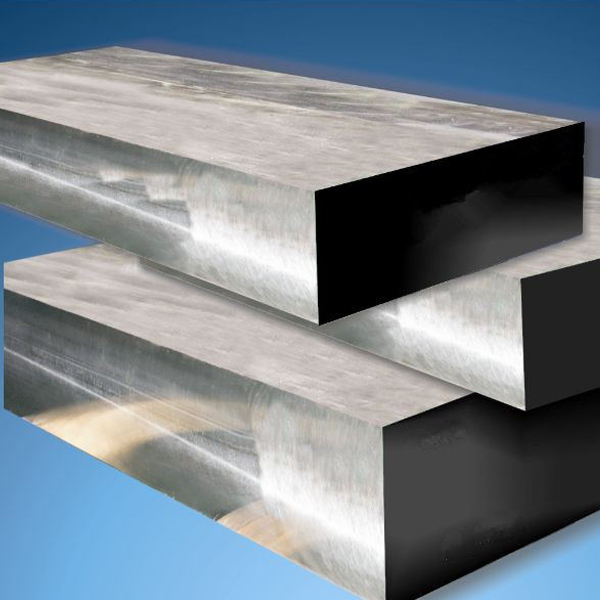

Loj:

|

KHOOM |

COJ COV CAI THIAB TXHUA YAM TXHUA HNUB |

|||

|

HLOOV BAR |

TXOOS NCO |

CENTERLESS GROUND |

TXIV |

NYEEM |

|

NTIAJ TEB HAUV HLI |

16-75 |

75-250 |

||

|

NYIAJ BAR |

KUB ROLLED DUB |

FORGED THAIV TAG NRHO SAB UA |

||

|

THICK X WIDTH IN HLI |

15X80-150X1000 |

80X500-200X1000 |

||